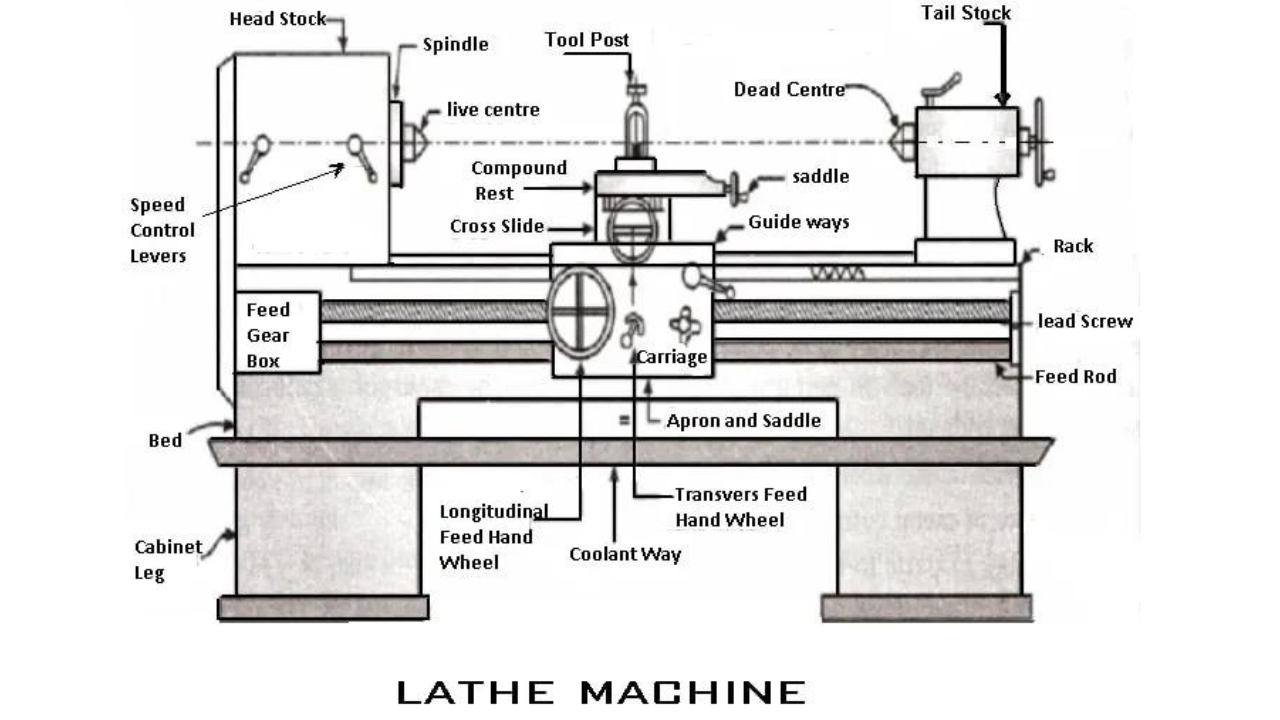

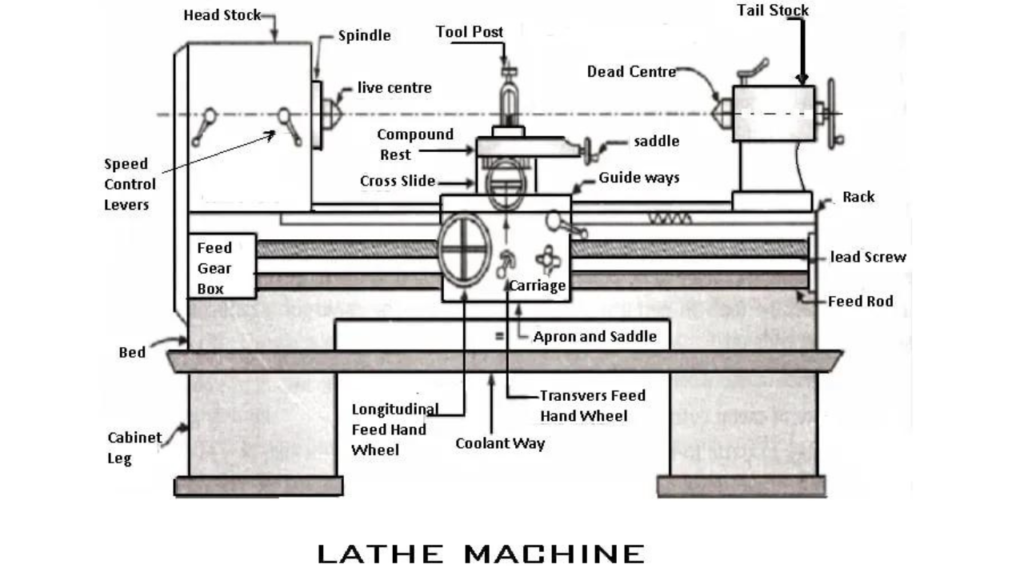

What is lathe machine?

The lathe machine is the most important machine in any workshop. To remove material from outside by rotating the work again a cutting tool.

Types of lathe machine operations :-

1) Facing.

2) Turning.

3) Chamfering.

4) Drilling.

5) Reaming.

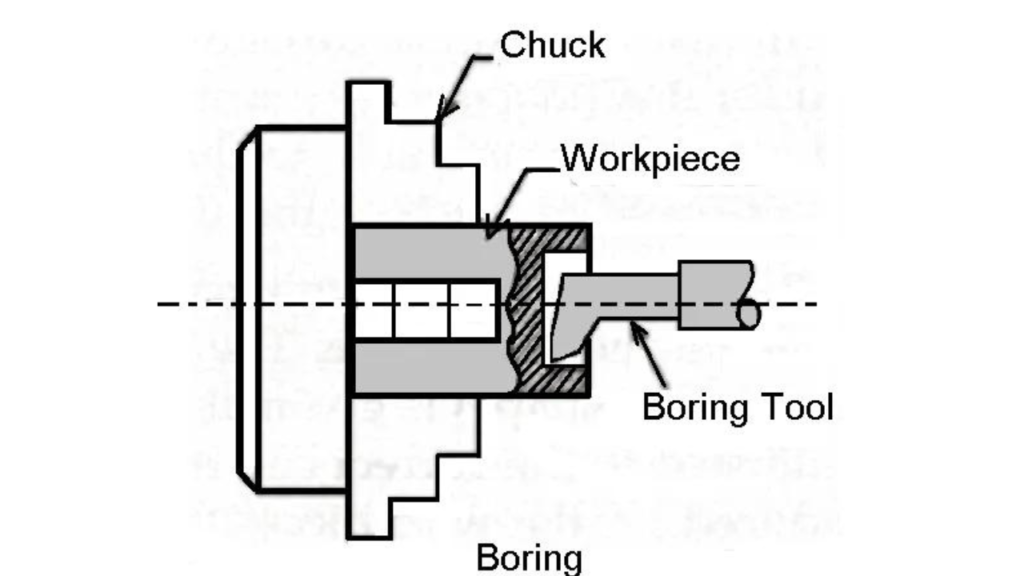

6) Boring.

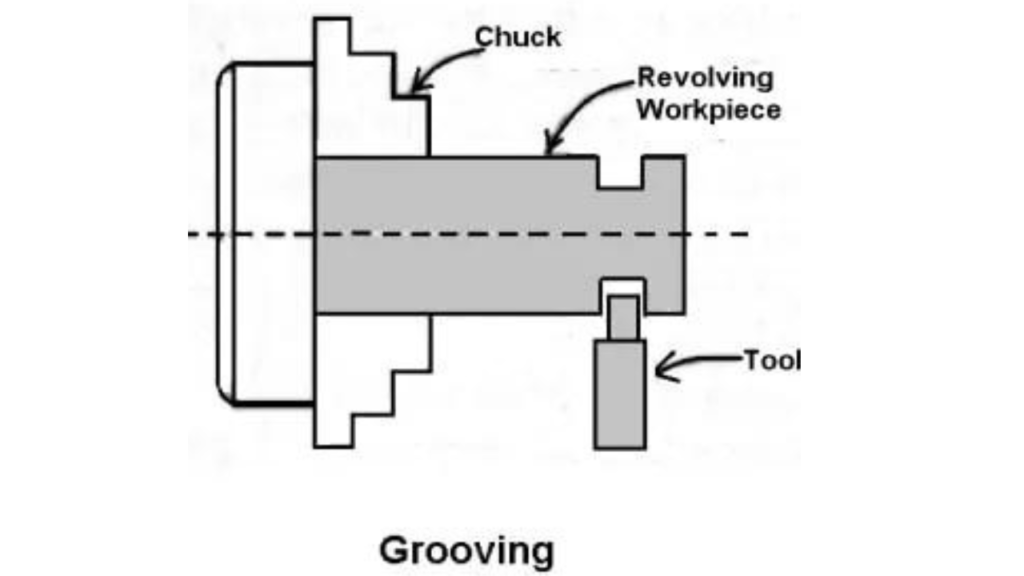

7) Grooving.

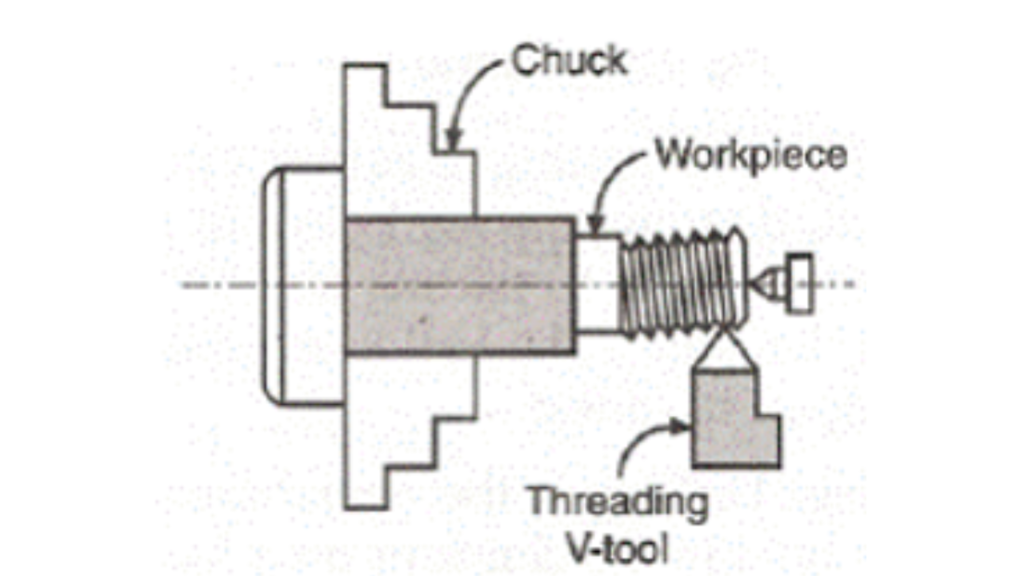

8) Threading.

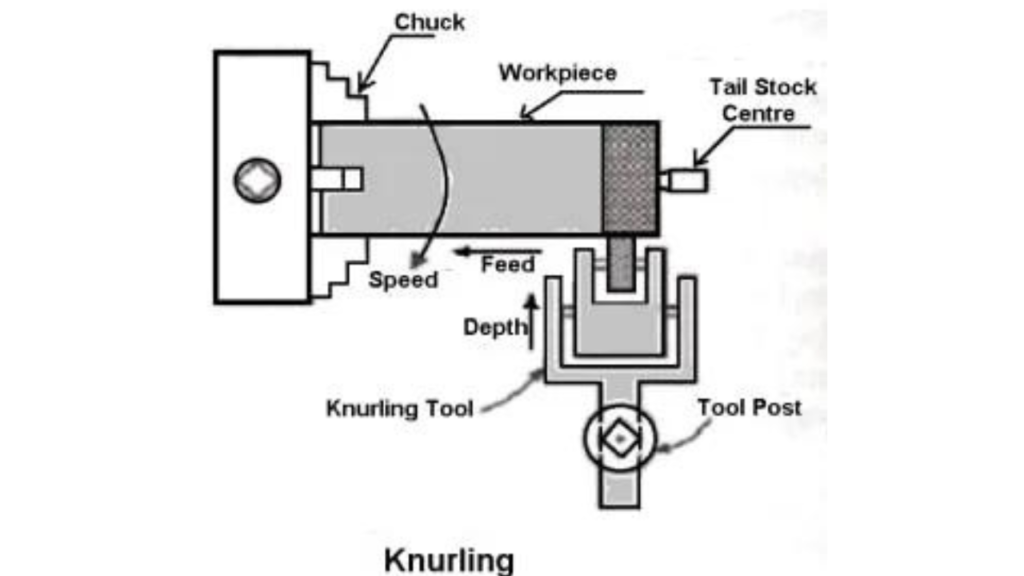

9) Knurling.

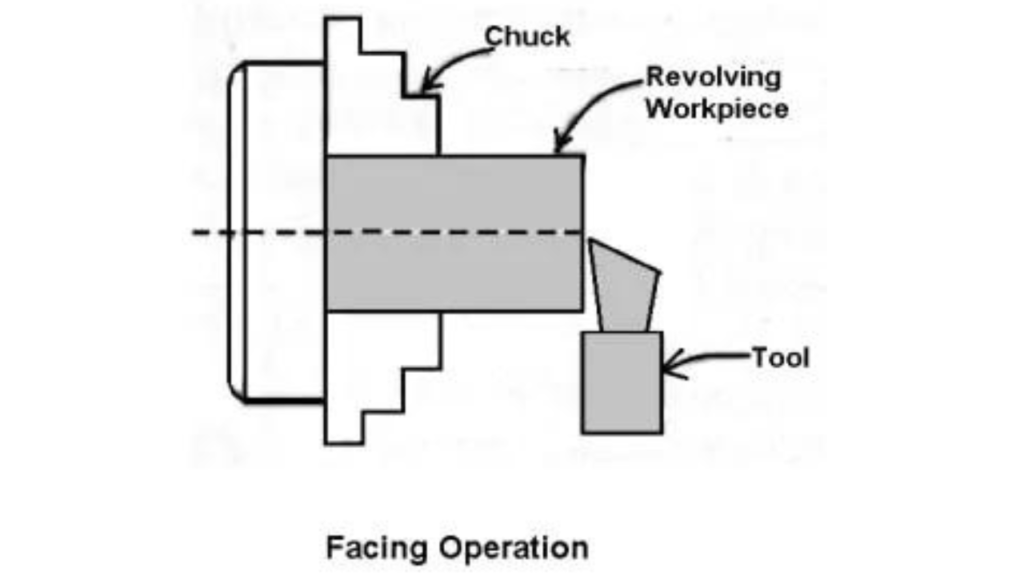

1) Facing :-

These operation facing almost essential for all work. In this operation the workpiece is held in the chuck and the facing tool is fed from the centre of the work piece.Towards the outer surface or from the outer surface to the center with the help of cross slide.

2) Turning :-

Two types of turning :-

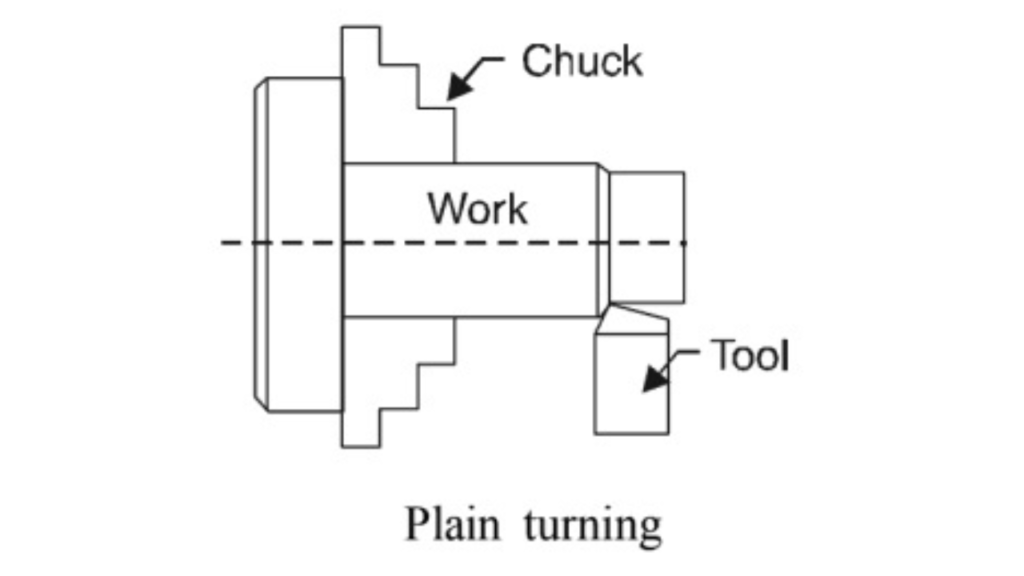

1) Plain turning :-

It is an operation of removing excess amount on material from the surface of the cylindrical work piece. In this operation the work is held either in chuck or in between centers & the longitudinal feed is given to the tool either by hand on power.

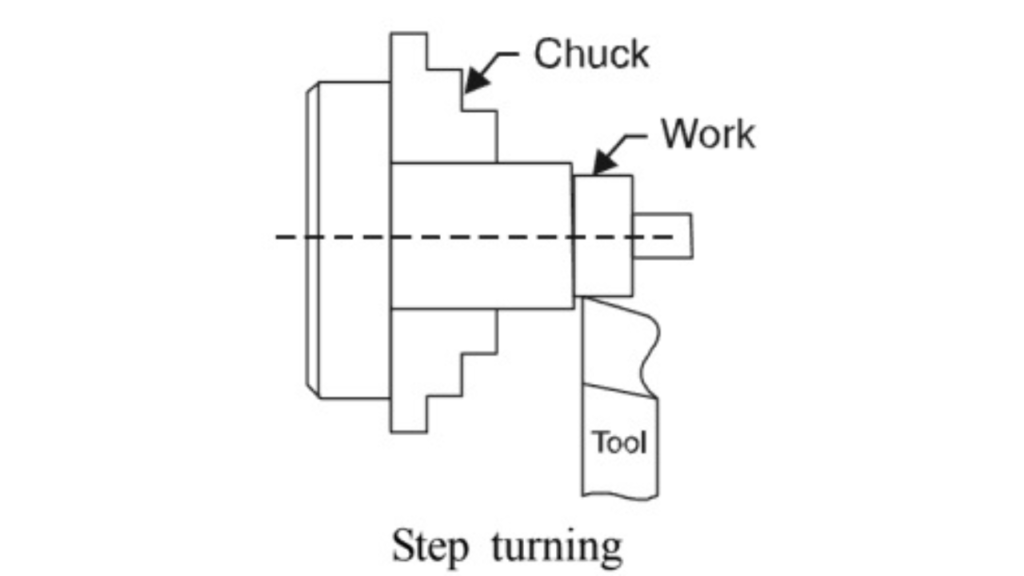

2) Step turning :-

It is an operation of producing various step of different in diameter in the workpiece as shown in fig. These operation is carried out in the similar way as plain tuning.

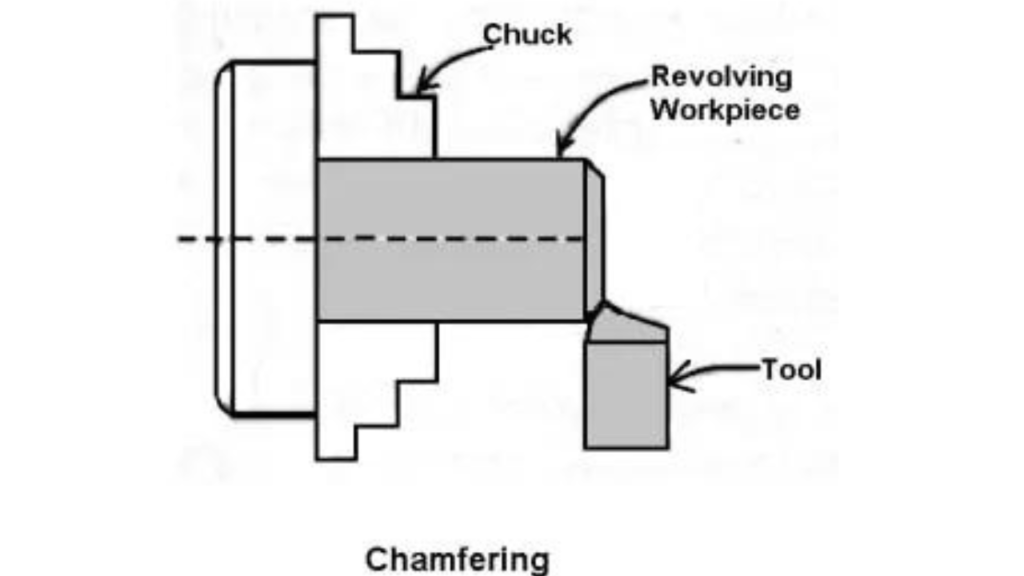

3) Chamfering :-

Chamfering is the operation of bevelling the extreme end of workpiece. This is done to remove the burrs to protect the end of the workpiece from the damage & to have better look.This operation must be perform after turning knurling ,boring, drilling or thread cutting.

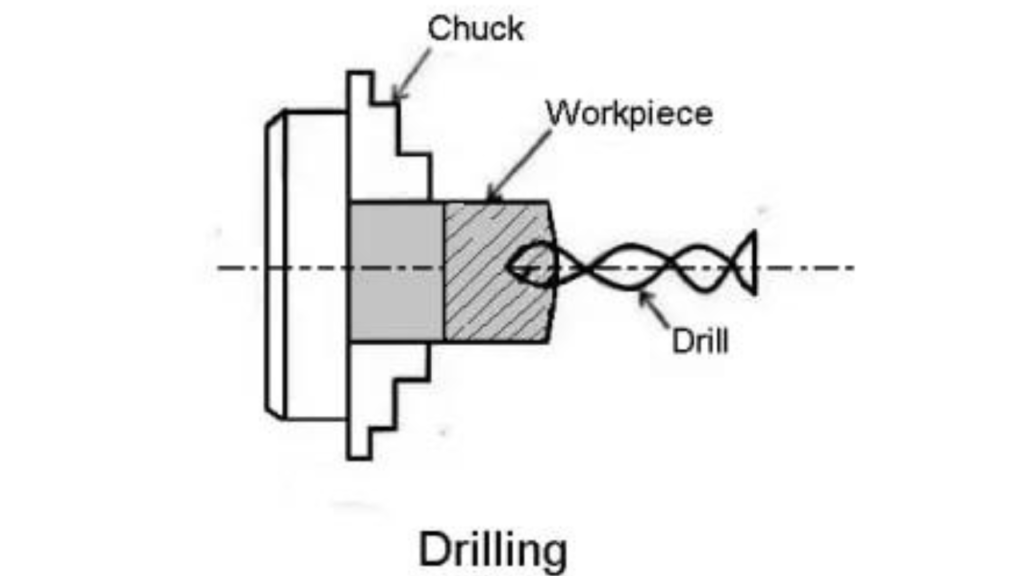

4) Drilling :-

It is an operation of making the hole in a work piece with the help of drill in this operation the work piece is held in chuck and the drill is held in the tail stock the drill is fed manualy into the rotating work piece by rotating the tailstock hand will.

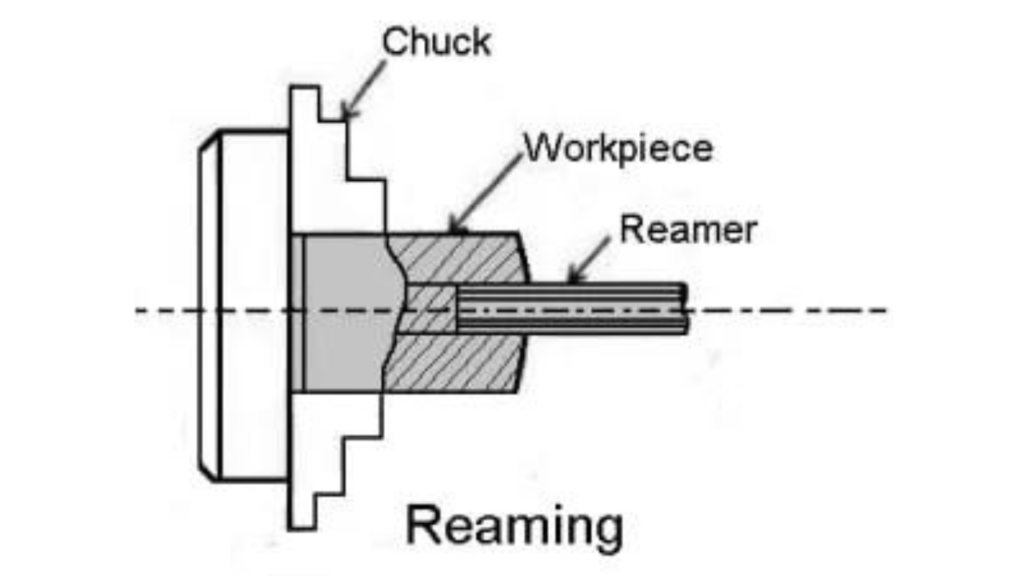

5) Reaming :-

It is the operation of sizing & finishing the previously drilled hole in this operation reamer held in the tail stock & it is fed into the hole in the similar way as for drilling.

6) Boring :-

1) It is the operation of enlarging of a hole already made in a workpiece.

2) In this operation boring tool or bit mounted on rigid bar is held in the tool post & fed into the work by hand or power in the similar way as for turning.

7) Grooving :-

1) It is an operation of reducing the diameter of work piere over a very narrow surface.

2) In this operation as shown in fig a tool of appropriate shape is fed into the revolving work up to the desired depth at right angles to the center line of the workpiece.

8) Threading :-

1) It is operation of cutting helical grooves on the external cylindrical surface of workpiece.

2) In this opertion the work in held in a chuck or between center and treading in fed longitudinal to the revolving work.

3) The longitudinal feed is equal to the pitch of the thread to be cut.

9) Knurling :-

1) It is operation an providing knurled surface on the workpiece. In these operation knurled tool is move longitudinal to a revolving work piece surface.

2) The projections on the knurled tool reproduce depressions on the work surface.

Thank You !!!

Kumar patil

श्री क्षेत्र बाळूमामा मंदिर आदमापूर

What is mechanism? & single slider chain mechanism types

What is inversion? Four bar chain mechanism types

What is kinematic chain? & Double slider mechanism types