Hello!! guy’s…. How are you?… I know you are also fine. Today we are going to learn discuss about steam condenser.

Dear engineering studends or Interested visitors, if you are searching for free study study notes. So, your come on a right place.

*STEAM CONDENSER :–

Definition of steam condenser:

It is a device in which is used to condense exhaust steam turbine into water.

It works to achieve two main objectives

1. The maintain low pressure (below atmospheric pressure) at the outlet of the steam turbine so as to obtain the maximum possible energy.

2. The supply pure feed water the hot well and from hot well the water is again pumped to the boiler with the help of boiler feed pump.

Advantages of steam condenser in steam power plant :

*Increases the efficiency of the plant.

* It reduce back pressure of the steam & thus more work can be obtained.

*It reduce temperature of the exhaust steam & thus more work can be obtained.

*The reuse of condensers as feed water for boilers reduces the cost of power generation. *Heat supplied per kg of steam to the boiler is reduced.

Classification of steam condensers :

The steam condenser may be broadly classified into two types, depending upon the way in which the steam is condensed.

1) Jet condenser or mixing type condensers :

These condensers are further classified as

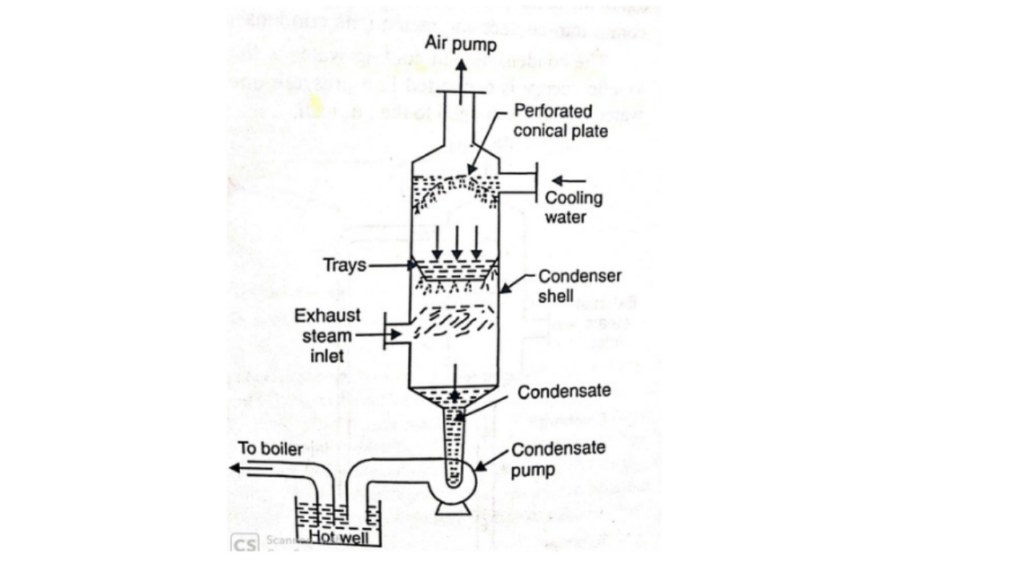

a) Parallel flow jet condensers.

b) Counter flow or low level jet condensers.

c) Barometric or high level condensers.

d) Ejector condensers.

2) Surface condensers or Non-mixing types condensers :

a) Down flow surface condensers.

b) central flow surface condensers.

c) Regenerative surface condensers.

e) Evaporative Condensers.

Jet Condensers :–

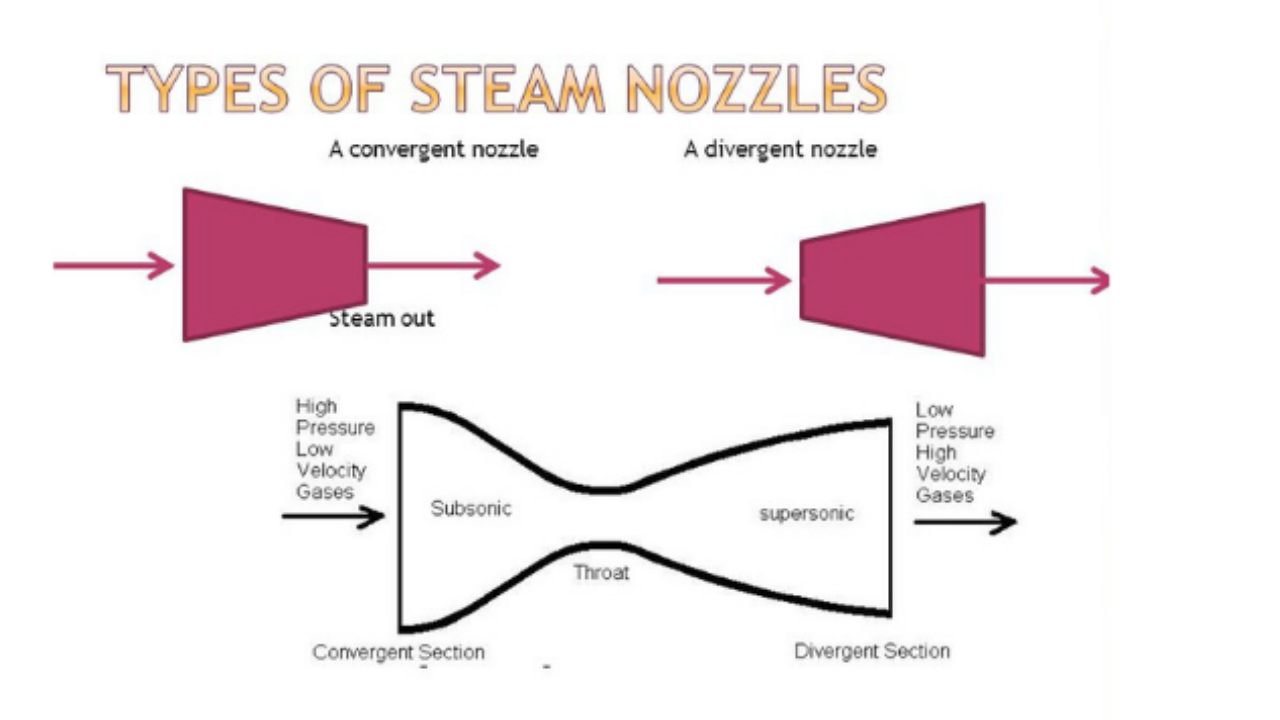

*The types of steam condensers is jet condenser in which the exhaust steam and water come in direct contacts with each other and temperature of the condensers is the same as that of cooling water leaving the condensate.

*The cooling water is usually sprayed into the exhaust steam to cause, rapid condensation.

*It is also called as mixing types condenser.

*Condensers (Two tube pass surface condenser) :

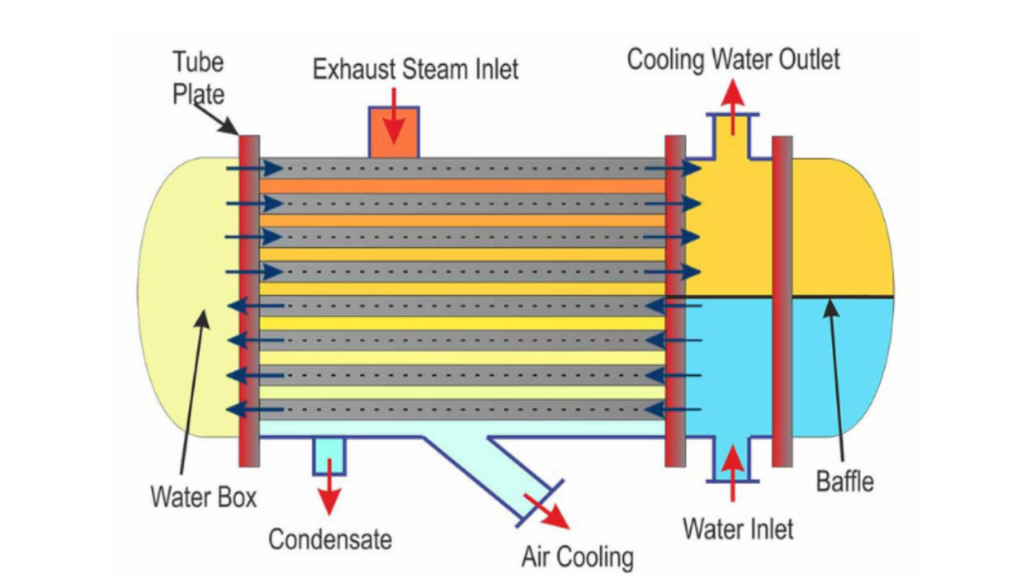

Surface condenser is the type of steam condenser in which the exhaust steam and water do not come into direct contact with other.

*The steam passes through the surface of tubes through which a supply of cooling water is maintained.

*The whole condenser can be used as boiler feed water.

*In such a condensate even impure water can be used for cooling purpose.

*It is called as non-mixing types condenser.

*It consists of an air tight cylindrical shell closed at each end as shown in the figure.

*A number of water tube is fixed in the tube plates which are located between each cover head and shell.

*The exhaust steam out of it the prime mover enter at the top of the condenser and surrounds the condenser tubes through which cooling water is circulated under force.

* The steam gets condensed as it comes in contact with the cold surface of the tubes.

*The cooling water flow in one direction passage through the first set of the tubes situated in the lower half of condenser and returns in opposite direction through the second set of the tubes situated in upper half of the condenser.

*Warm cooling water coming out from the condenser is discharged into cooling tower, river or cooling pond.

*The condenser is take out from the condenser by a separate extraction pump and air is removed by an air pump.

*Types of Surface Condensers :

Surface condenser on the basis of direction of flow of condensate, the arrangement of the tubing system and the extraction pump is the position are classified as :

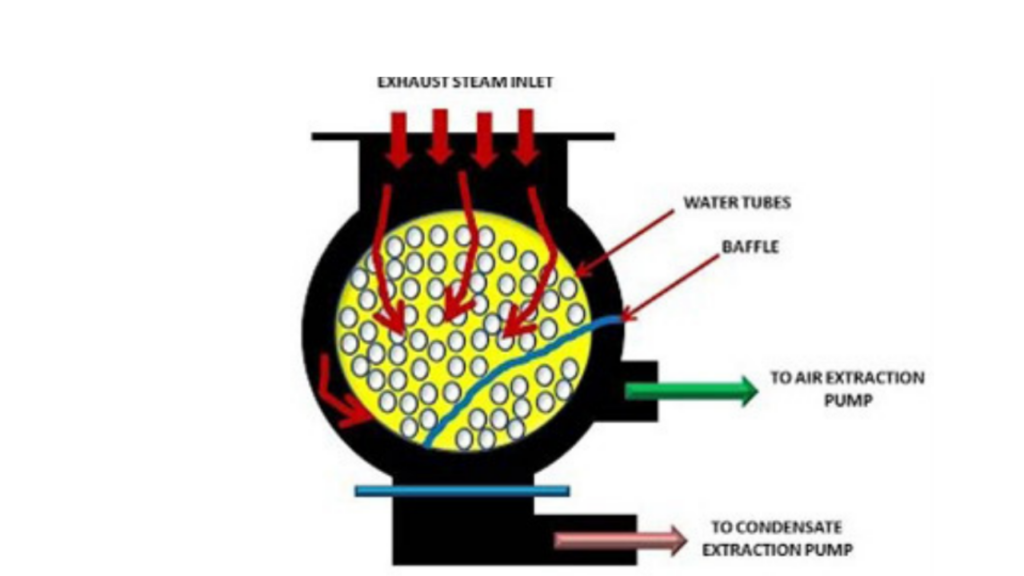

*Down Flow Surface Condensers :

*In down flow surface condensers, the exhaust steam enters at the top & flow downwards over the tubes due to force of gravity as well as section of the extraction pump sitting the bottom.

*The condensate is collected at the bottom & then pumped by the extraction pump.

*Dry air pump section pipe, which is provided near the bottom, is covered by a baffle so as to prevent the entry of condensed steam into it as shown in figure.

*The direction of flow steam is perpendicular of flow of cooling water (inside the tubes), this is also called as cross-surface condenser.

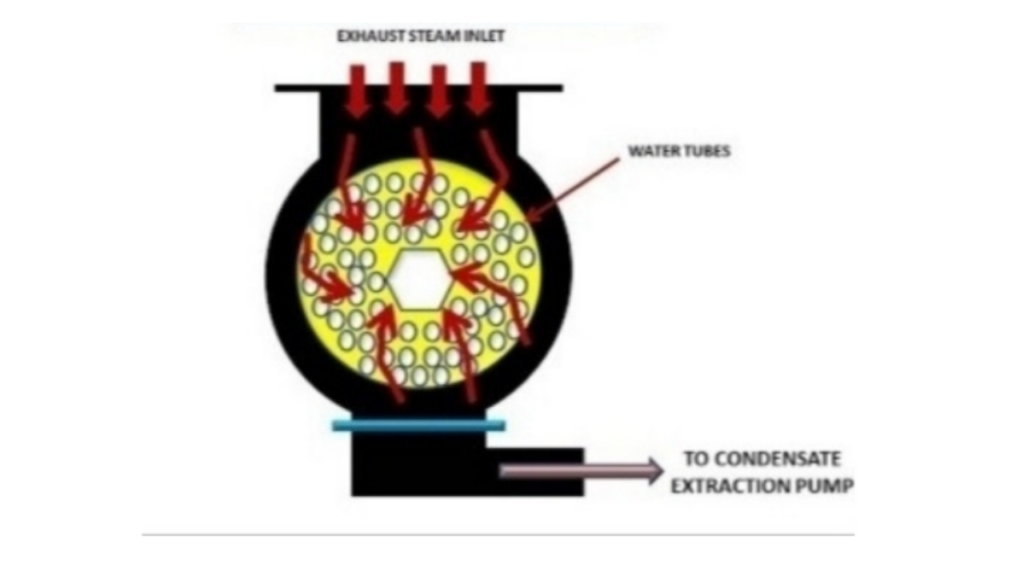

*Central Flow Surface Condensers :

*In central flows surface condenser, the exhaust steam enters at the top & flow downwards. The section pipe of the air extraction pump is placed in the centre of as shown in figure.

* This causes the steam to flow inwards over the tubes towards the section pipe.

*Condensate is collected at the bottom & then pumped by the extraction pump.

*The central flow surface condenser is an improvement over the down flow type as the steam is directed radially inwards by a volute casing around the tube nest.

*Regenerative Surface Condensers :

*In regenerative surface condensers, the condensate is heated by a regenerative method. The condensate after leaving the tubes is passed through the exhaust steam from the engine or turbine.

*It thus, raises it is temperature for use as feed water for the boiler.

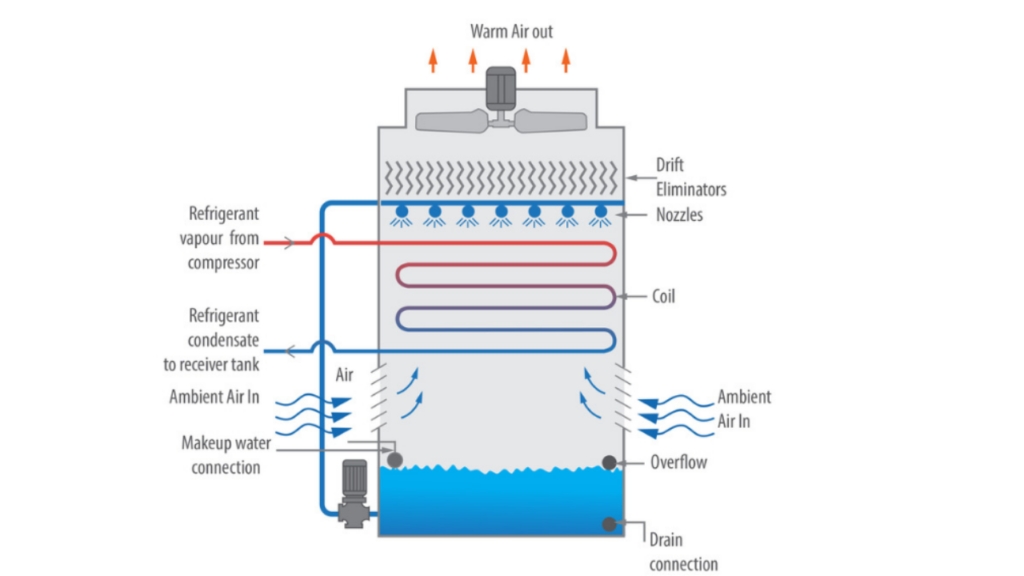

*Evaporative Condensers:

*The steam to be condensed enters at the top of a series of pipes outside of which a film of cold water is falling.

*At the same time, a current air circulate over the water film, causing rapid evaporation of some of the cooling water.

*As a result of that, the steam circulating inside the pipe is condensed.

*The remaining cooling water is collected at increased temperature and is reused. It is original temperature is restore by the add of the requisite quantity of cold water.

*These condensers consist of sheets of gilled piping, which is bent backwards and forwards and placed in a vertical plane as shown in figure.

*Application : The evaporative condensers are provided when the circulating water is to be used again and again .

Good kumar sir ? ?

Thanks sir…. ???❤

Nice notes…..??

Thank you….. ?

Nice sir….?