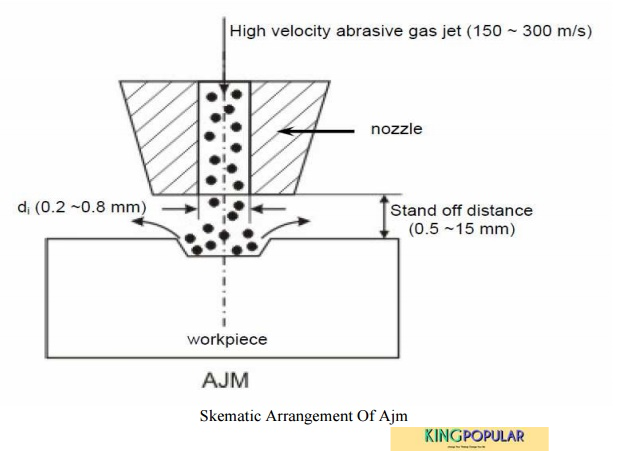

Working Principle of AJM :-

Abrasive jet machining process -working principle, process parameters, Advantages,Disadvantages & Applications: 1) Abrasive jet machining process that removes material from a workpiece with the help of abrasive Particles.

2) The Process differs from sand blasting is that in AJM the abrasive particles has much smaller diameter of about 0.025 mm.

3) The process consist of mixture of fine abrasive particles and gas at high pressure.

4) The stream of mixture is directed through a nozzle on to the surface of the workpiece as shown in fig.

5) The abrasive particles impact on the workpiece at high speed.

6) As the particle impacts the surface, it cause’s small fracture of the work surface which results in removal of metal.

7) The gas stream Carries both the abrasive particles and the fractured (wear) Particles way.

amazon affiliate account kaise banaye / अमेज़ॅन एफिलिएट अकाउंट

The important process parameters in Abrasive jet machining are :

1 ) Abrasives :-

i) The abrasive material used is Al2O3.

ii) The grain size is around 25 um.

iii) The shape abrasive is generally Spherical.

iv) The mass flow rate is 3-10 g/min.

2) Gas carrier :-

i) The type of gas used is air, N2o Or Co2.

ii) The air density is 1.3kg/m velocity 150-300 m/s and Pressure 2-8 bar.

iii) The flow rate is around 30 L/min.

Nozzle 8-

i) The nozzle is made of Tungsten carbide or Sapphire.

ii) It’s shape is circular, 0.3-0.5 mm internal diameter or rectangular (0.08 mm 0.51mm) to 6.61 mm ,0.51 mm).

iii) The tip distance is 0.25 – 15 mm.

iv) The life of wc is 12-30 hour and sapphire is 300 hours.

v) The operating angle is 60° to 90° the surface.

Google web stories कैसे बनाएं/ Google web stories kaise banaye

Advantages of Abrasive jet machining : –

I) Intricate cavities and holes of any shapes can be easily machines.

ii) Brittle material of thin section can be easily machined.

iii) Low initial investement is required.

iv) No direct contact of tool and workpiece.

v) Amount of heat generated is not apperciable.

vi) Normally inaccessible portions can be machined with fairly good accuracy.

Google AdSense information in marathi

Disadvantages of Abrasive jet machining :-

I) Low metal removal rate.

ii) Once used abrasive particles canot be reused.

iii) Not suitable for machining of ductile material.

iv) Relatively poor machining accuracy.

v) There is possibility of abrasive particle getting in the work material, hence cleaning needs to be necessarily done after the operation.

How to change payment method while making a purchase in Google Play

Applications of Abrasive jet machining :-

i) Fine drilling and micro welding.

ii) Machining of semi conductors.

iii) Frosting and abrading of glass articles.

iv) Machining of intricate profile hard and fragile materials.

v) cleaning and cutting operations on material like germanium, Silicon , quartz, mica.

vi) Machining of brittle materials like glass, ceramics refractories etc.

Thank you for visiting?

Electric Discharge machining process- Working Principle, Advantages, Disadvantages & Applications

IPL 2023 time table,टीम, स्थान, समय सारणी, पीडीएफ, अंक तालिका, रैंकिंग

IPL 2023: सभी 10 टीमों के लिए निश्चित रिटेन टीम और खिलाड़ियों की सूची

147 वाढदिवसाच्या हार्दिक शुभेच्छा -Happy birthday Wishes in marathi

TATA IPL 2022 Schedule,Match, Date & Time l IPL Timetable photo

TATA IPL 2022 Team Player List

How to Start Tissue Paper Manufacturing business/टिश्यू पेपर निर्मितीचा व्यवसाय

Jio के 5G टैरिफ प्लान क्या हैं?&5G Radio Platform

Jio 5G: प्लान, सिम, लॉन्च की तारीख, शहर, स्पीड टेस्ट

What is milling machine? & Classification

आधारकार्ड डाऊनलोड कसे करावे / How to download Aadhaar card

Plastic moulding – Types, Advantages, Disadvantages & Applications

How to download Instagram video & photo

अहिल्याबाई होळकर भाषण/निबंध/माहिती/Ahilyabai Holkar information in marathi